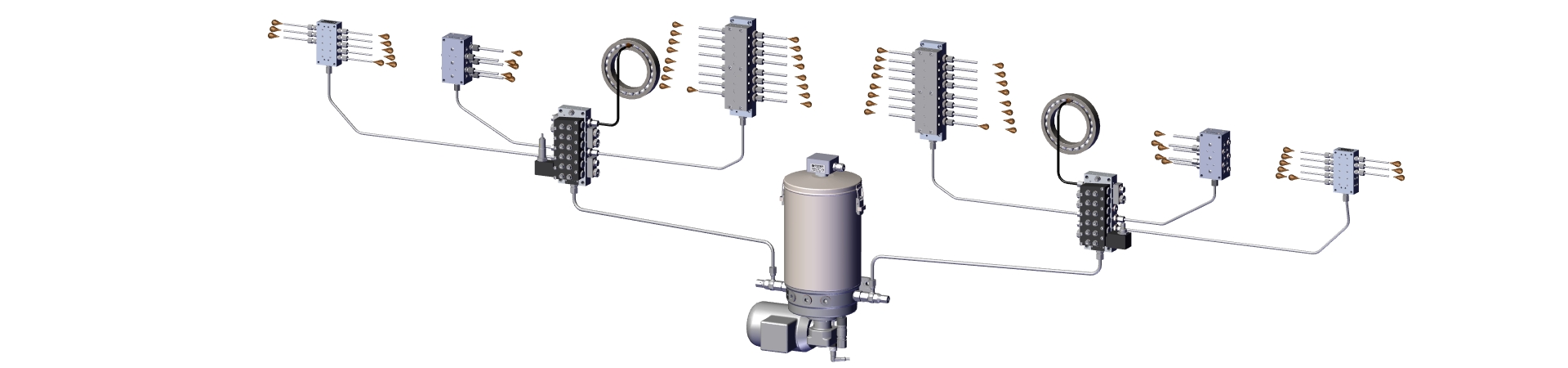

Progressive Lubrication System

Description of the system:

Progressive distributors are piston distributors, which separate the lubricant fed along the main line to the various outlets. The pistons of the metering elements are moved in a specified order. This movement causes the pistons to displace lubricant, which is pumped through an outlet to the lubrication point. The order of lubricant assignment is specified. Should a distributor remain in a certain position (system switched off, line pressure too high, storage tank empty etc.), then the allocation of lubricant continues at the same position at which it was interrupted when the system restarts.

The distributors in this system work on the basis of forced control. This means that in a complete distributor circuit all the outlets are supplied with the specified volume of lubricant. The forced control of the metering pistons means that there is safe functional control just by monitoring one piston.

Benefits:

- Minimal pressure loss (start-up pressure)

- Cost-effective monitoring

- Large varying lubricant volume ratios are possible between the outlets

- Thin oils, liquid grease and grease up to NLGI class 2

- Pressure up to 350 bar

- Precise metering

Functional principle progressive distributor

Our high quality progressive distributors, also called piston distributors, are designed to realize the most environmentally friendly and low starting pressure. The moving parts are hardened to increase the life of the product. The video shows the function of a progressive distributor.

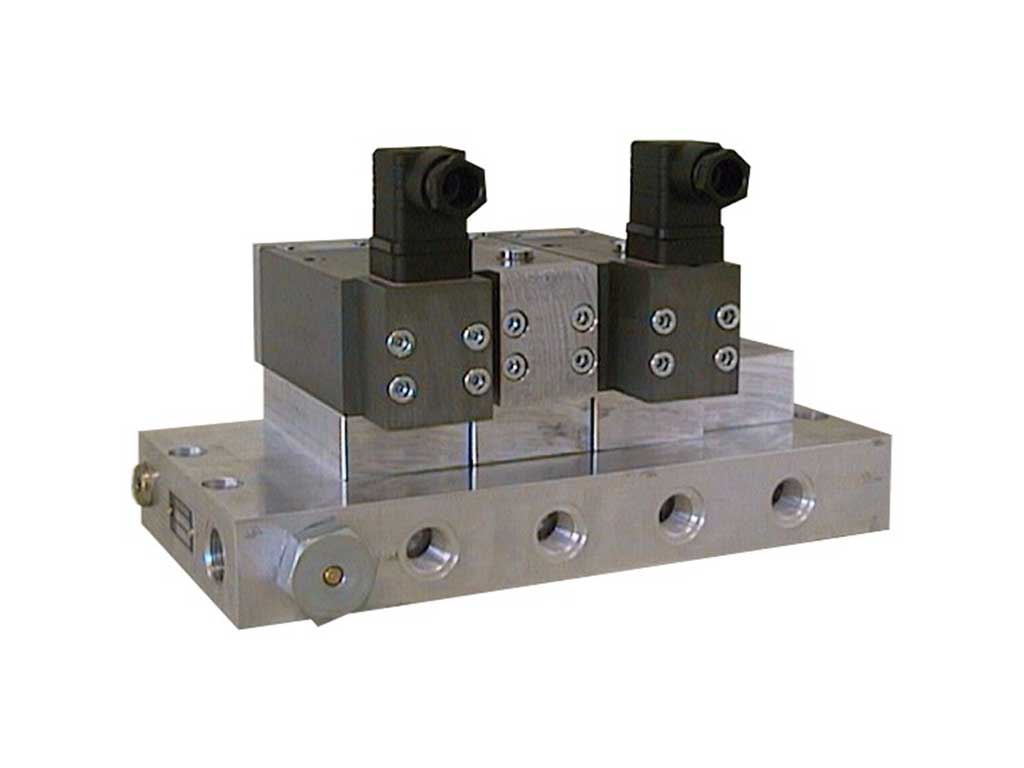

Types:

WOERNER progressive distributors can be sub-divided according to:

- Element design (VPI)

- Plate design (VPA)

- Block design (VPB)

Supply of distributors:

Multi-line pumps, among others, can be used to supply the progressive distributors with the required feed volume, and are often referred to in the literature for this application as progressive pumps.

These pumps are designed to meet various requirements, such as the volume to be pumped and requisite pressure. The volume needs to be high enough to supply the lubrication points and the pressure needs to be high enough to overcome resistance in the pipework and friction in the distributor.